Paper & Board Machines

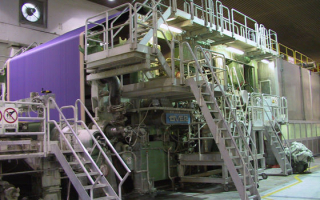

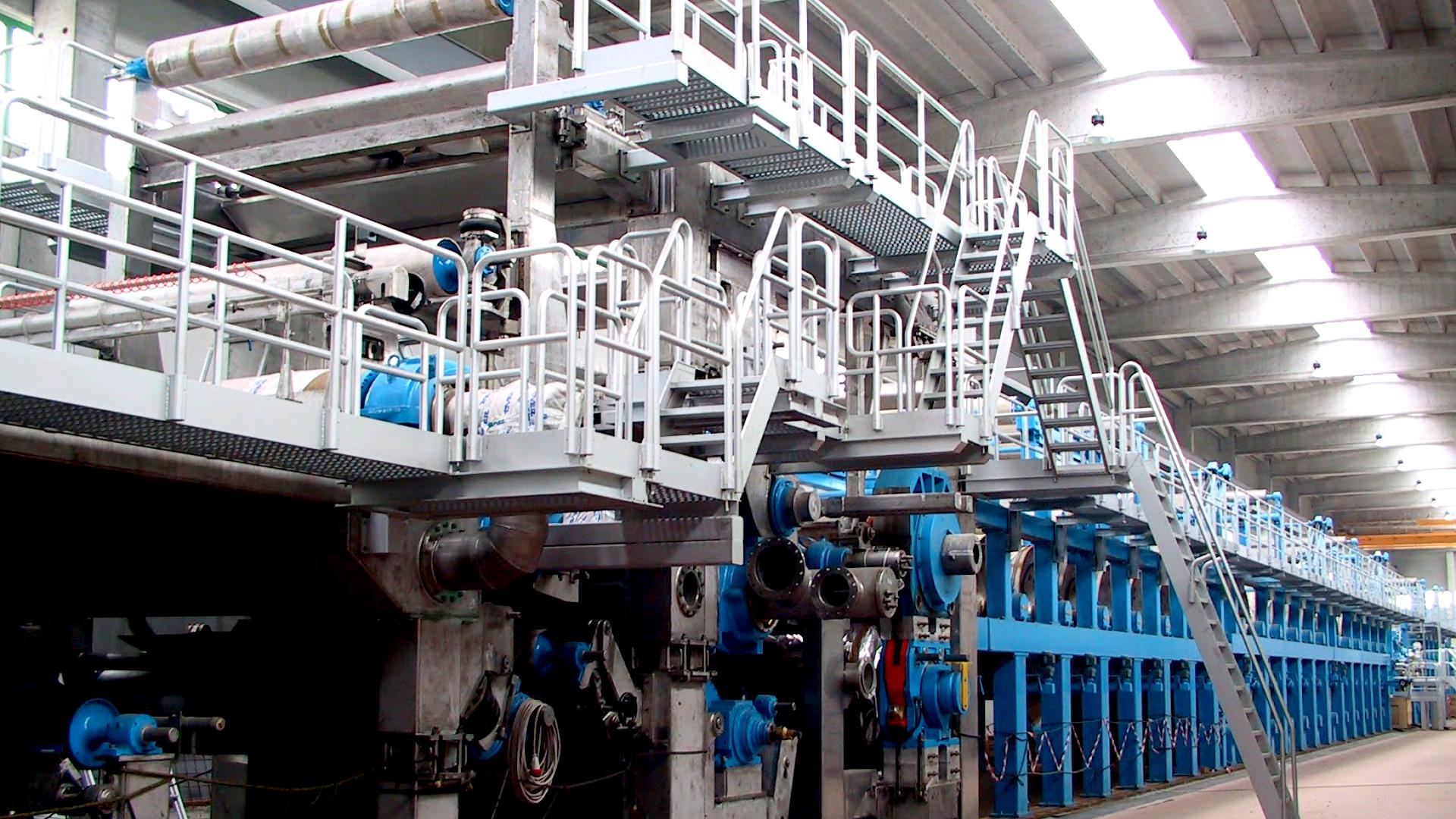

Our Paper & Board machines meet a wide range of market needs: from the small line, with a production capacity of 100 tpd, to the wide and fast one with output capacity of 1,300 tpd.

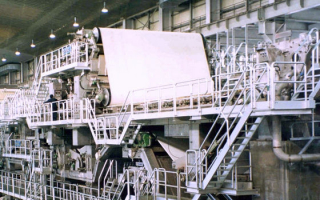

The modern board and paper-making machine, based on the Fourdrinier Machine, is basically composed by a conveyor belt or wire where a pulp of fibers and water is poured. Such pulp passes through various sections to be drained, pressed, heated and calendered to obtain paper.

Each paper type, from writing paper, printing paper to paper board has its own characteristics, as for example the basis weight, that are achieved with specific processes, but in general the paper machine is composed by:

- Forming section or wet end, where the pulp coming from the headbox is poured on the wire and filtered,

- Press section, where the pulp is squeezed to remove as much water as possible,

- Drying section, where the sheet gets dehydrated through a series of heated rolls,

- Calender section, where the paper is smoothened,

- Reel section, where the paper gets rolled up into jumbo rolls that will then moved to the winder.

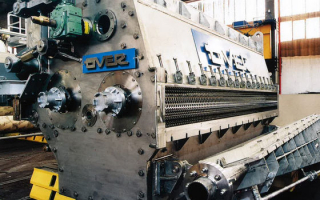

The core business of Overmade is such paper machine. Over the years more than 200 completely new machines and 120 major rebuilds have been manufactured and supplied, covering the production of every grade of paper: writing & printing, newsprint, packaging papers, board, special papers.

Our Paper & Board machines meet a wide range of market needs: from the small line, with a production capacity of 100 tpd, to the wide and fast one with output capacity of 1,300 tpd. All the installed components are always optimized for the specific use, thus forming product families, within which common technological features are shared and adapted to the particular application. OVERMADE has the capability to manufacture machines with rolls-width up to 10,000 mm, and operating speed up to 2,200 mpm.

Information requestPaper & Board Machines

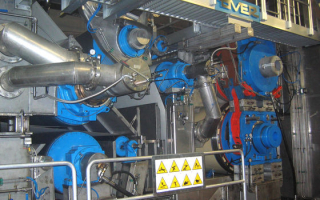

- Headbox

- Formers

- Presses

- Dryer sections

- Size presses

- Calenders

- Reels

- Rolls